R-MES

Traditional Blow Molding had difficulty shaping a flange, but R-MES is the technology to do this by Injection Molding or by using parison of Blow Molding.

The concept of combining this technology and Exchange Blow Molding technology allowed the traditionally metal framed parts to be replaced to plastic; Therefore, weight and cost reduction have been achieved.

Basic Concept of R-MES

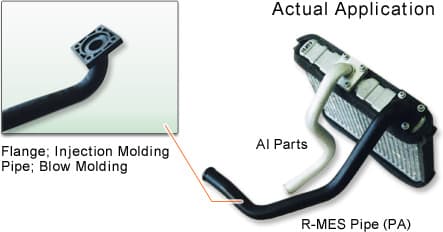

The concept of R-MES : a blow molded main part and flange are formed with plastic.

The flange can be formed by blow molding parison or by injection molding.

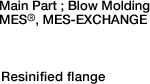

Application of R-MES Molding Process for Turbo Air Intake Duct

Below shows a traditional aluminum formed flange being replaced to plastic by glass fiber reinforced nylon.

Weight and cost reduction are possible and also the designing flexibility is increased.

Application of R-MES Molding Process for Coolant Pipe

Flange is shaped to the end of 3D crooked pipe by Injection Molding.