MES

Multi-dimensional Extrusion System

This is the first developed Multi-dimensional Extrusion System technology in the world.

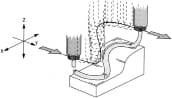

This is a blow molding technology in which the mold and die head, which extrudes the parison (cylindrically melted resin), are moved relative to each other and the parison is stored in a horizontal mold cavity.

Advantages of Multi-dimensional Extrusion System

- Minimal loss during molding

- High degree of flexibility in design (shape), including 3D shapes and inserts

- High-performance engineering plastics can also be molded

Conventional Blow

MES®

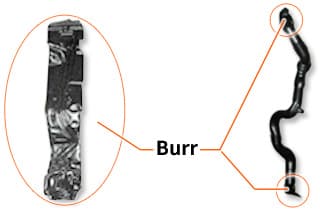

MES Blow Molding can significantly reduce losses (burrs) during molding compared to general blow molding.

Compared to conventional blow molding, it has less material and energy loss during molding.

MES Blow Molding works well with inserts, which integrate subcomponents such as brackets by setting them in the mold in advance and molding them, making it possible to propose reductions in the welding process.